I just completed my third year of at Rowan University, and I thought I would share my latest engineering clinic project...A lot of work went into this thing.

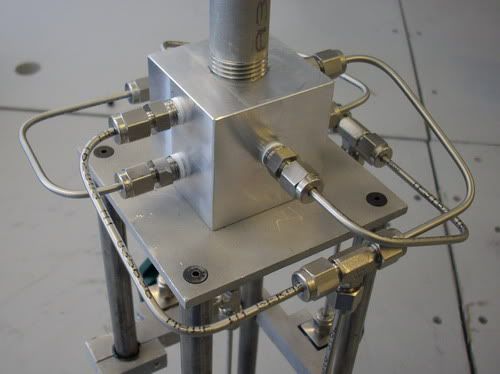

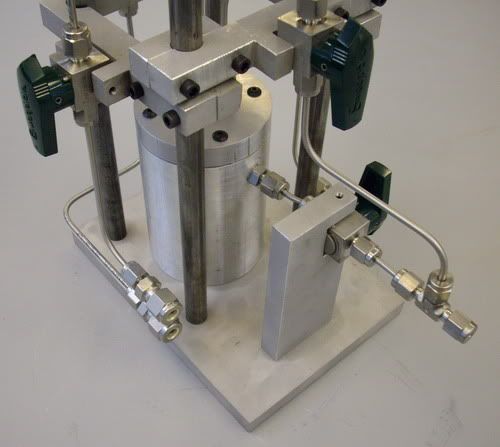

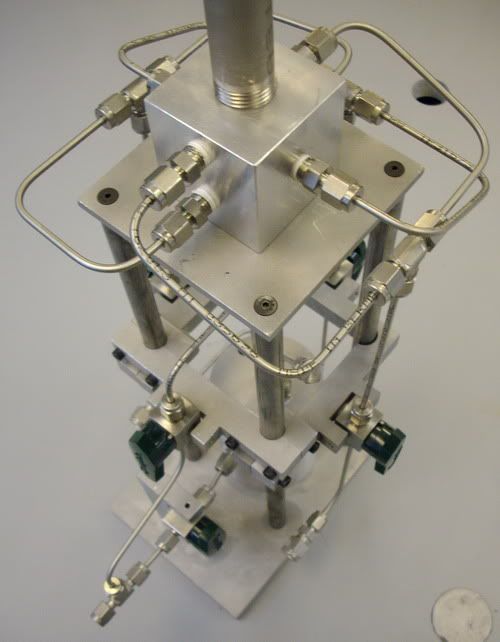

This was a first year project, so my team of 3 had no background on combustion theory or nano particle creation. We had to design and construct a facility for manufacturing nano particles, and we came up with this co flow burner. This facility is unique because it is portable (only 20" tall), and the delivery system for the particles is attached under the burner.

This was a full semester course worth 2 credits!...2.5 hour class twice a week.

Everything was built at Rowan by me and one other of my team members(he just got a firebird btw). 76 machine hours went into the facility alone.

The chamber shown on the lower portion gets inert gas pumped through it, which becomes saturated in the liquid precurser(to make nanoparticles) inside. It then exits the chamber and gets forced up to the top stack of tubes where the flame is produced. The layers of the top stacked tubes put out an oxider, fuel(methane), and a shroud gas(nitrogen) to contain the oxidizer/fuel mixture. Basically a pimped out bunsen burner for controlling gas mixtures.