So this weekend was generally productive. On Saturday. the car was put in the air to fix the bent drivers side LCA relocation bracket, realign the rear and remove the trans. Maybe the clutch and bellhousing depending on time.

Rear LCA relocation bracket out. I'd say that was a bit bent. I replaced both sides just to make sure everything was in good order. Measured, measured and measured so everything should be nice, straight and centered. Took me what felt like forever but I'm relieved that's all that got wrecked with the suspension. It was also a good reminder to go through a nut/bolt check. I noticed a few attachment points to be not loose but not tight either.

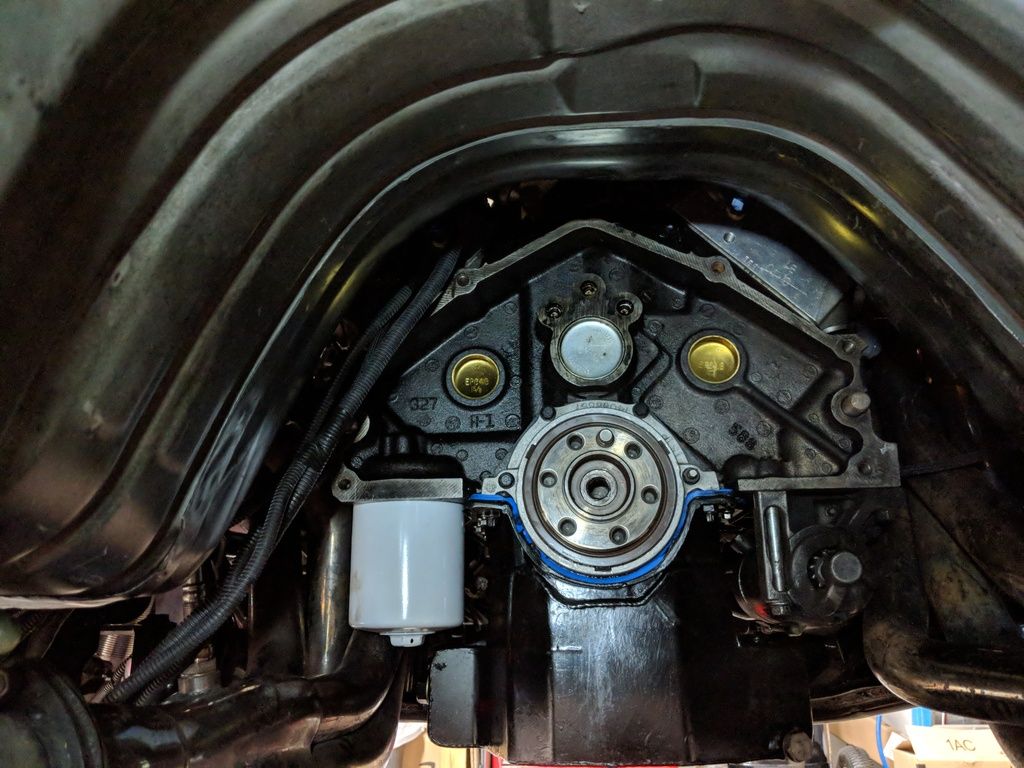

Next was the trans. No real progress pics here. Just out! Everything went pretty smoothly, almost as if it's been done before.... I'm happy with myself for not laying down a thick bead of RTV for the shifter base plate. It popped off pretty nicely. I used an assortment of lengthy extensions to grab the top bolts on the trans. Overall, time consuming but not horrendous. I had it out in about 2.5-3hrs. Again, really pleased I went with quick disconnects for the trans fluid lines. I think maybe a couple drops trickled out on the initial yank but that was it. I was pretty surprised to notice the Y-pipe I painted with high temp black paint a couple seasons ago has returned to it's natural color. Everything was cleaned and prepped so am I to assume heat burned it off? I may wrap the pope later on. As for the trans, there is not much to look at but the input shaft tip looked perfect but lateral slop in the input felt def "out of spec".

Pictured below - That could be trans fluid or blood.... My hands must be baby soft as I managed to remove quick a bit of skin even with gloves on.

New radio still looks good!

The last schlepping of the trans off the trans jack to the dolly properly tired me out so I was done for the day. I honestly couldn't believe how filthy. I threw out my shirt and took a very long shower.

Sunday arrived and it was time to get the bell and clutch out. Everything was going well until I hit the two upper bolts on both sides of the tunnel. I recall the install happening with the engine in the car but I'm not quite sure how we did it. No tool I had would get to the allen head bolts. Sockets and even an allen wrench were too long. I tried a bit of prying to angle the engine back to get something on but no luck. Ginger anger ensued. Out came the cutoff wheel (thanks Adam) and I shorted both the allen wrench and the socket with the allen. I didn't bother measuring and just hacked away. To my surprise, my modified tools were able to get the job done and out came the bell.

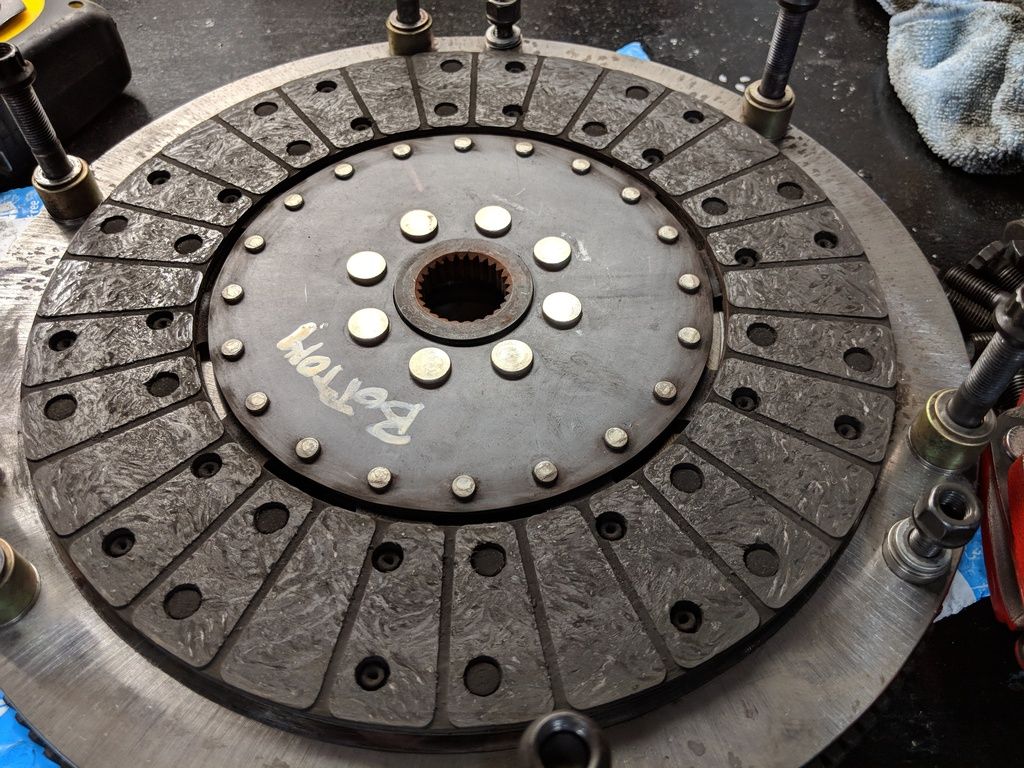

Next came the clutch. Feeling the end of the effort ahead, this thankfully went super smooth. My cordless impact (Thanks again Adam) made quick work of the flywheel bolts and it was done. The clutch looks worse than it really is. The metal surfaces can be cleaned up and the discs show a good amount of material remaining. I showed my Dad and immediately blamed him for the hot spots likely caused during his 1.4x 60' pass

.

So that's it for now. The clutch and bell are for sale. Once I see what's up with the current trans, that will be for sale as well.

Time to order new parts.....