Bringing folks up to speed, I decided to turbo the car given I don't seem to like money, needed a winter project, a pal was upgrading his turbo, sold the Caddy and had a very willing friend ready to cut/weld with me. The work kicked off towards the end of the year and been working on it progressively almost every weekend.

The turbo is on and the car runs which is all quite nice. I plan to take a maiden voyage soon once some more keyboard work is done plus install of the boost controller this coming Saturday. A number of things were learned along the way.

1. Just because you think you have room doesn't mean you have room for more things.

2. Brick and mortar is entirely useless for small items that they used to stock

3. Cutting/grinding metal makes a lot of mess

4. I'm pretty good at making braided lines

Turbo location was the obvious tricky thing on this car. As I said there is room but also no room so we decided the best position would be on the passenger side and in front of the manifold flange. This would provide good height to allow for the oil drain to do its thing while giving a path for the downpipe. We needed to move the radiator as far forward as possible even with this placement given as I said, lack of room. A new radiator was purchased to give as much clearance as possible.

Hooker manifolds were used and overall were nice pieces however the crossover pipe they sell could have lined up on the flanges a touch better. The crossover does fit as tight as possible between the trans and engine. After many pie cuts, the downpipe was welded up and the only path was to feed it in the pocket between the k-member and lower control arm. The pipe then shoots back to the aftermarket exhaust that was on the car. The passenger side pipe was cut and then joined to the drivers side for a pseudo y-pipe.

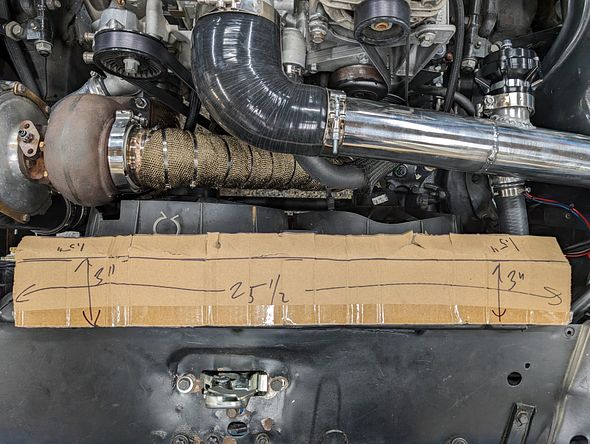

Up front, the largest intercooler that would fit reasonably was installed with some custom bracketry. From there, a good bit of silicone couplers and aluminum tubing got the cold side knocked out. I purchase a bead roller from amazon which actually worked pretty well on the aluminum tubing. Timing cover came off to weld in a -10AN fitting for the turbo drain. New timing cover seal and water pump seals went on thereafter along with a new crank bolt. A Summit wastegate will chooch to atmosphere and a Summit BOV will hopefully make fun noises.

Not pictured yet are turbo snuggie, new fuel rails, regulator, and braided lines as the prior system I cobbled together used a C5 regulator/filter, push lock hose, stock LS1 injectors etc. I didn't go crazy with the new stuff but my hope is it supports around 500rwhp. The injectors are Deka 80lb sticks but still running a 255/340 pump.

Video below was running off the original tune with the prior fuel system. Intent was to see if it had any issues and confirm no leaks etc.

https://hosting.photobucket.com/imag..._205743061.mp4

Fan shroud is being made up by a friend so should have that within a couple weeks.

Car is way quieter than it was before which is actually kind of nice. It had way more bark than bite previously so having that toned down a bit is ideal.

Can't thank Chris (wretched73) enough for all the hours he put in and his welding skills. He also had to put up with me which was probably the biggest challenge.

More to come but that should be good for now.